Purdue University Alumni and entrepreneur Dr. Katherine Clayton pivoted many times throughout her career. From working on her Mechanical Engineering degree to researching public health in cholera endemic regions to developing technology to prevent food borne illness, Clayton’s journey has taken her to many industries, across the country and the world. Now, Co-Founder and CEO of San Francisco-based OmniVis, Clayton is aiming to reduce foodborne illness across the country utilizing the skills she learned from I-Corps and other innovation programs.

Dr. Katherine Clayton and the OmniVis team

Innovative Research at Purdue

Clayton’s journey started while working toward her Mechanical Engineering degree at Purdue. Interested in diagnostics, she eventually started collaborating with biomedical engineers to develop an innovative way to detect pathogens.

“I was working on a project between professors in the School of Mechanical Engineering and the School of Biomedical Engineering. Originally, we were trying to find ways to detect different biological phenomena using just a microscope and some particles and whatever biological entity that we wanted. We were using it to look at how two different proteins interacted with each other or to look at how drug degradation could happen.” – Dr. Katherine Clayton

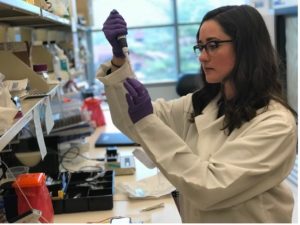

Clayton Researching at Purdue University

Clayton participated in numerous business competitions and innovation programs with this innovative technology, including Local I-Corps at Purdue. She utilized the technology to study public health – namely pathogens such as malaria and cholera. After completing Purdue’s I-Corps program, she and her team moved on to the National Science Foundation’s I-Corps program in 2018.

Traveling the world with NSF I-Corps

Clayton honed her customer discovery and entrepreneurship skills through NSF I-Corps’ rigorous curriculum. As part of the national program, she was given funds to travel across the country and the world to interview potential customers in the global health space. One of her notable destinations was Haiti. While there, she saw firsthand the challenges communities were facing when battling illnesses like cholera.

Clayton Visiting Clinics in Haiti

“They try to teach you during I-Corps that you need to ‘get out of the building’. We were working on global health, so to get out of the building and to be truly global, you had to leave the country… I think if I had not gone to Haiti and met these experts, I wouldn’t be able to connect the dots as fully with what we were working on.”

OmniVis and Food Safety

After years of research and customer discovery, Clayton and her team pivoted and entered the food safety industry. Their company, OmniVis, creates handheld pathogen-testing devices for food manufacturing.

“We created a handheld device to be able to detect foodborne pathogens in under 30 minutes… We’re focusing on food facilities first because, believe it or not, they already test every single week for foodborne pathogens in their facilities. They’re doing everything they can to protect us. So, we want to be part of that strength of what they’re already doing.”

Mockup of Future OmniVis Product

Manufacturers test their facility environments for pathogens frequently. However, in the current approach, testing is often sent to an outside laboratory. This delay can cause illness-causing pathogens to slip through the cracks. OmniVis’ technology allows for rapid on-site testing. This greatly reduces the chance that foodborne illness will go undetected in a manufacturing facility.

Excitement for the Future

OmniVis is currently pre-revenue, working to overcome the regulatory hurdles of bringing its product to market. However, Dr. Clayton is excited about a world where more manufacturers can test for pathogens. It can potentially reduce illness, improve people’s lives, and more.

“When I envision the potential of this technology, particularly in the realm of food safety, my initial focus lies on ensuring its widespread implementation in food manufacturing facilities across the United States. By accomplishing this, we can harness the vast amount of data generated by our devices and process it in an anonymized and aggregated manner. With this comprehensive data, we can gain invaluable insights into identifying the periods of highest risk for foodborne outbreaks in our country’s food facilities. Then we can ascertain when instances of foodborne illnesses are most likely to occur. Ultimately, this knowledge empowers us to prevent people from falling ill due to contaminated food.”

Interested in I-Corps? Check out our upcoming courses:

https://www.greatlakesicorps.org/events1/list/

Quotes Edited for Clarity

NSF I-Corps Hub: Great Lakes Region, 2023

Written by Chris Eakin